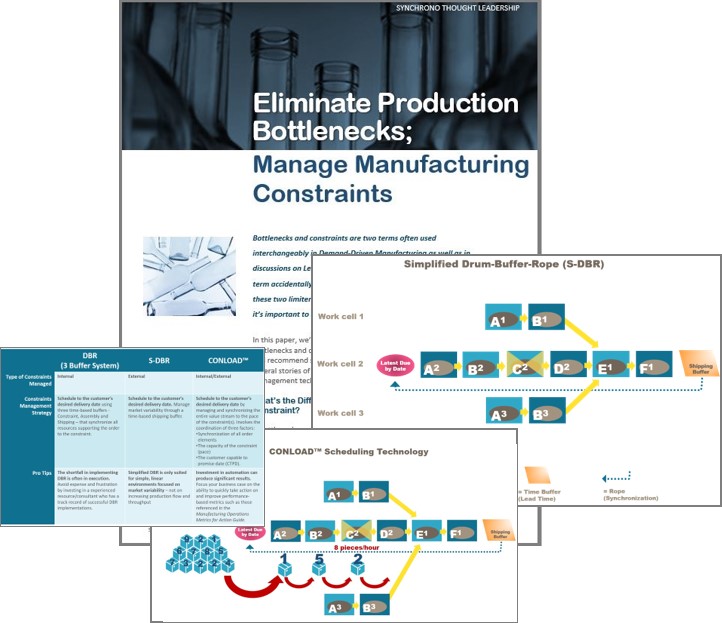

White Paper: The Next Generation of Planning and Scheduling Solutions

This paper provides a customer/order-centric view of manufacturing planning and scheduling that focuses on synchronizing man, material, method and machine to produce an order in the most efficient way possible. This approach drives the system – and those who use it – to optimize flow through the entire system rather than individual components. Focusing on flow through the entire process leads to increased throughput and ultimately impacts the bottom-line.